|

|

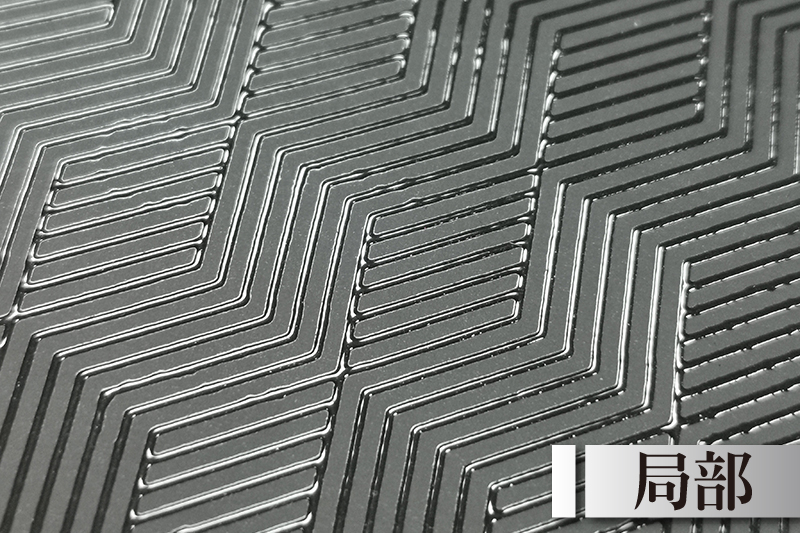

※local light

This kind of glazing method can show a vertical effect on the visual and tactile surfaces, and the fog film is often applied before partial glazing, and the effect is the best.Scope of application: Suitable for general printed matter, such as packaging color boxes, book covers, large posters, paper bags, etc.

|

|

|

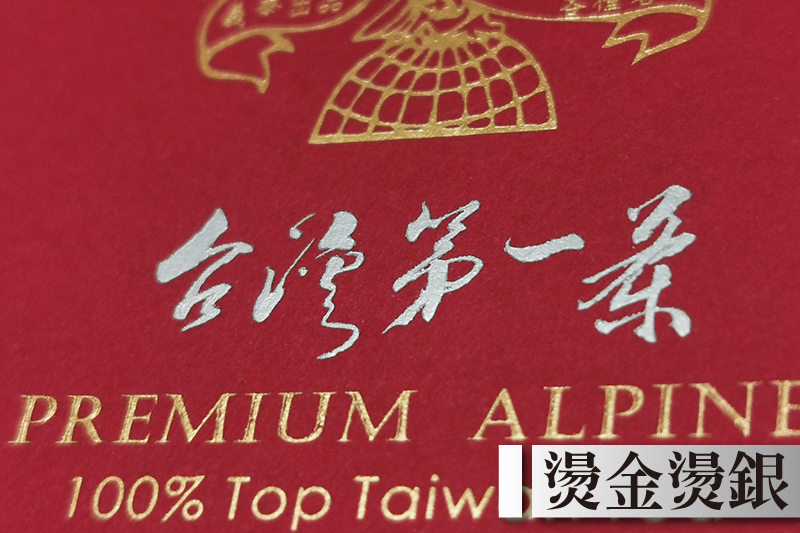

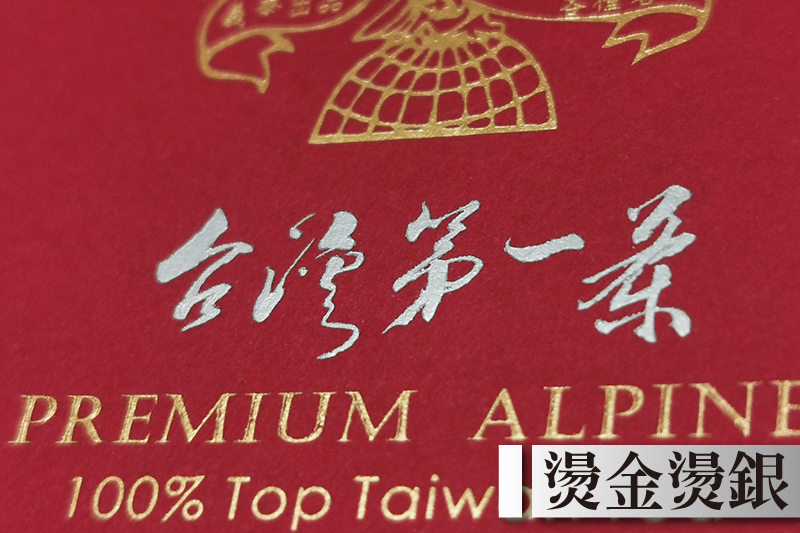

※Bronzing method

Hot stamping is to emboss gold foil on the printing surface by means of heat and pressure: if varnish UV coating is used, hot stamping cannot be used.

Scope of application: often used in advanced packaging boxes. For example, cosmetics, health food, portable gift boxes, wet paste boxes and other high-priced commodity packaging boxes.

|

|

|

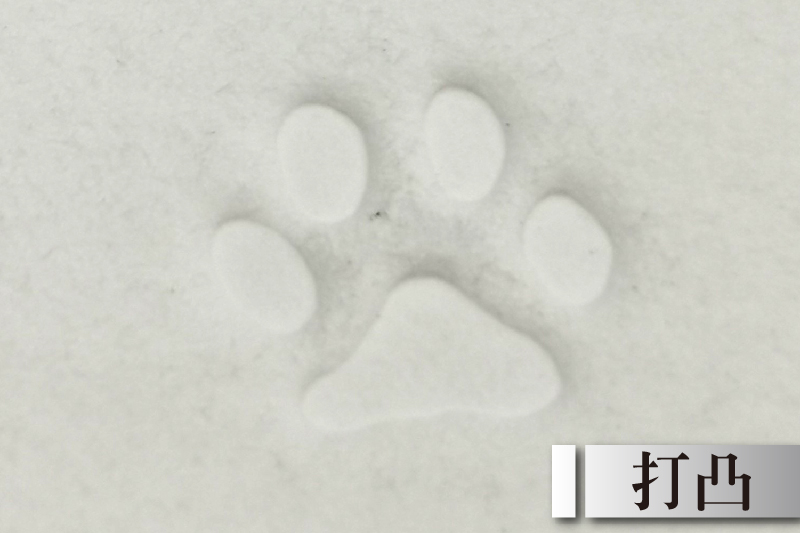

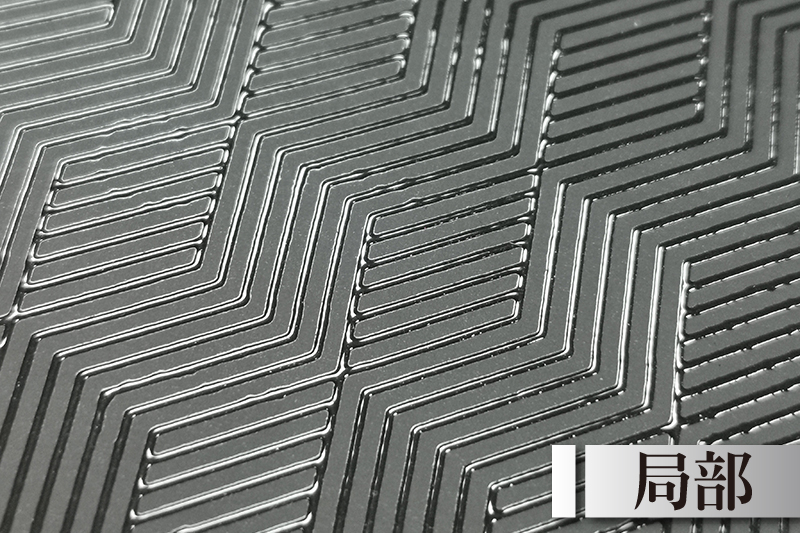

※Embossing method

For embossing, first make a letterpress, and then apply a certain pressure on the surface of the paper to produce an immediate effect. At the same time, if it is combined with bronzing or partial glazing, the effect will be even better!

Scope of application: It is often used in high-end packaging boxes, such as cosmetics, health food, portable gift boxes and other high-priced commodity packaging boxes.

|

|

|

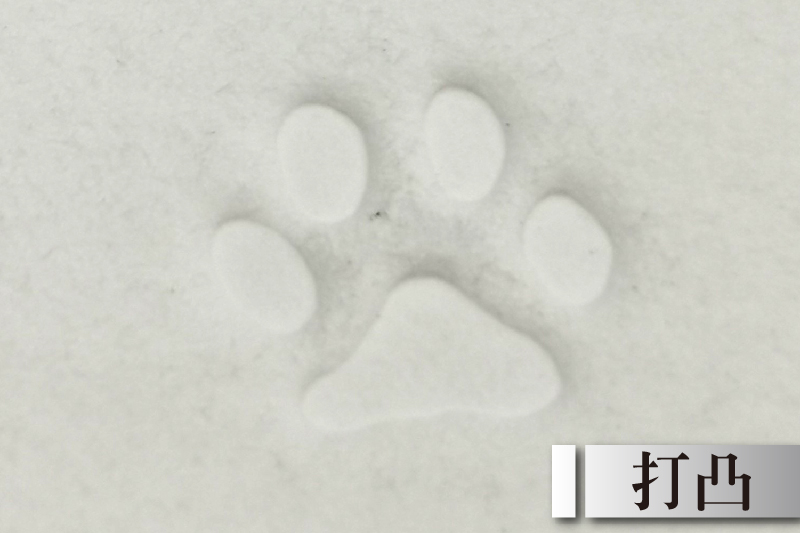

※Dimple method

Using mechanical pressure, the embossed effect of the paper surface is presented through the embossed plate. It is often used to highlight the layered texture of the catalog cover, paper box, paper bag, packaging products, cards, etc.

|

|

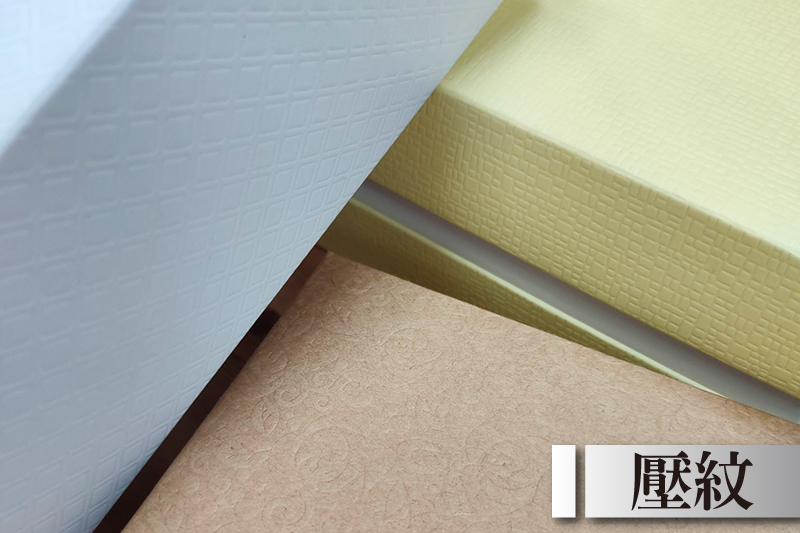

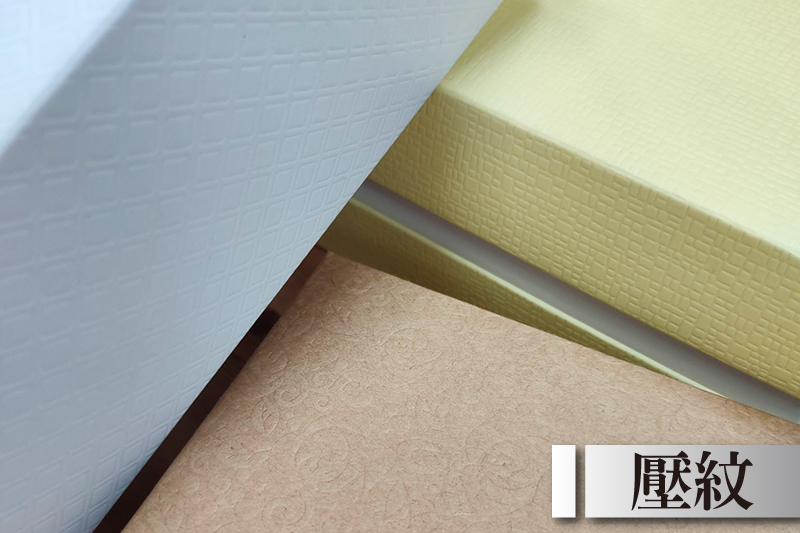

※Embossed

Different from embossing, the embossing is a uniform texture on the whole surface, which makes the packaging have a three-dimensional effect different from the plane. For example, wood grain, grid pattern, fine corrugation, etc., so that ordinary white cardboard can also have a special texture like art paper.

|

|

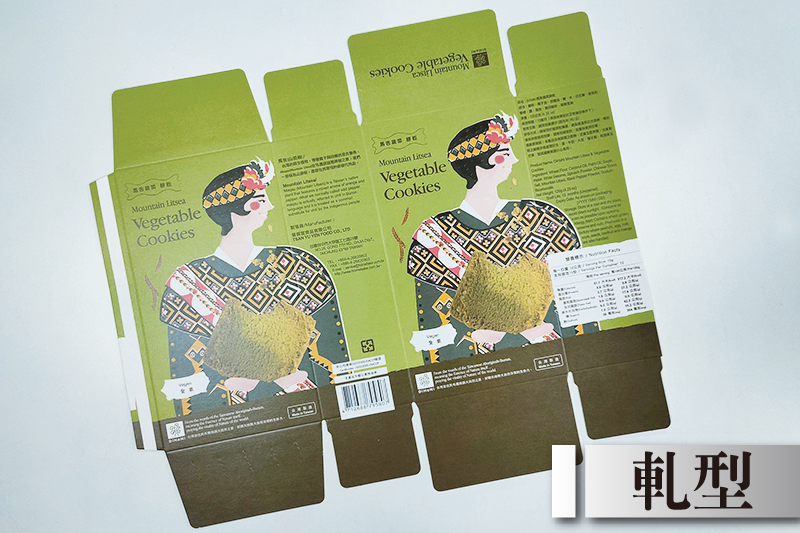

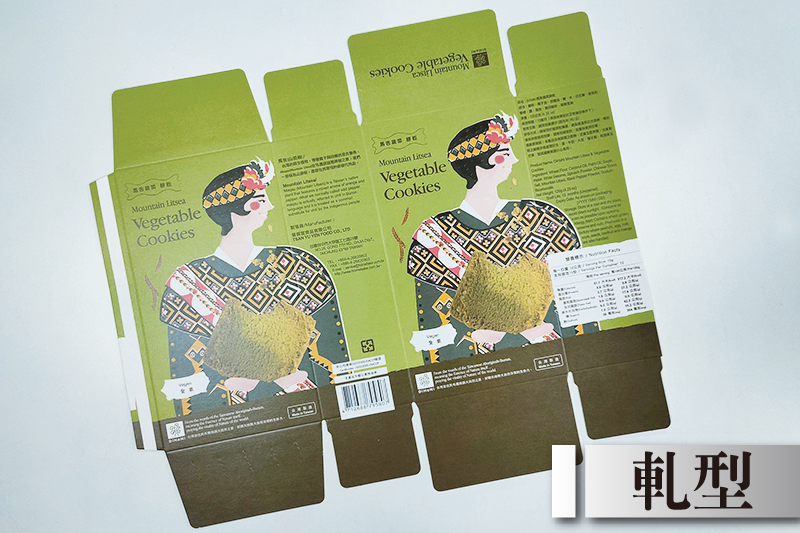

※cut type

Also known as "rolling type", any finished product related to shape, carton forming, high-pound paper bag creasing, etc., which is not cut and delivered, generally undergoes a cutting process; the paper surface is precisely pressed by a knife die to make the plane The paper is shaped and creased to achieve the shape of the finished product. The knife mold can be used repeatedly.

|

|

|

※Window OPP

Usually, windows are opened on one side or both sides of the packaging carton. On the one hand, it can display the contents, and on the other hand, it can also let customers know more about the products inside the packaging box. It mainly depends on whether the product has both appearance design. characteristic.Scope of application: It is often used in packaging boxes, such as sporting goods, cosmetics, health food, electronic products, etc., where it is necessary to display the appearance of the product.

|

|

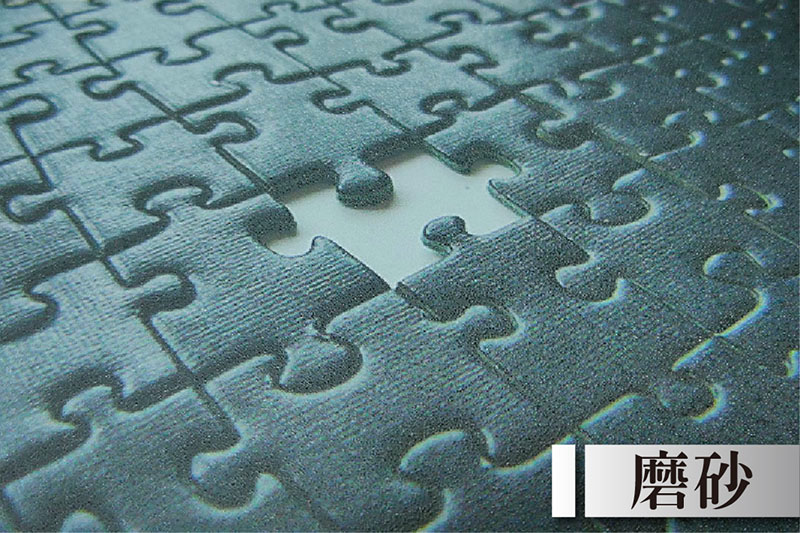

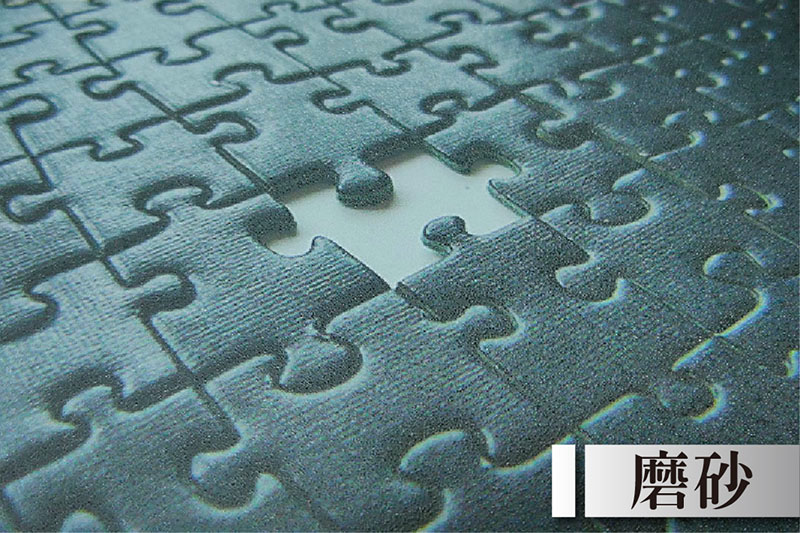

※frosted

Matte processing can present a rough surface with protruding grains on the whole or partial surface of the carton, paper bag, cover and other packaging; "The texture is similar to sandpaper, but it does not scratch hands. The roughness can be divided into coarse, medium and fine grain sanding, which has a unique effect in packaging products.

|

|

|

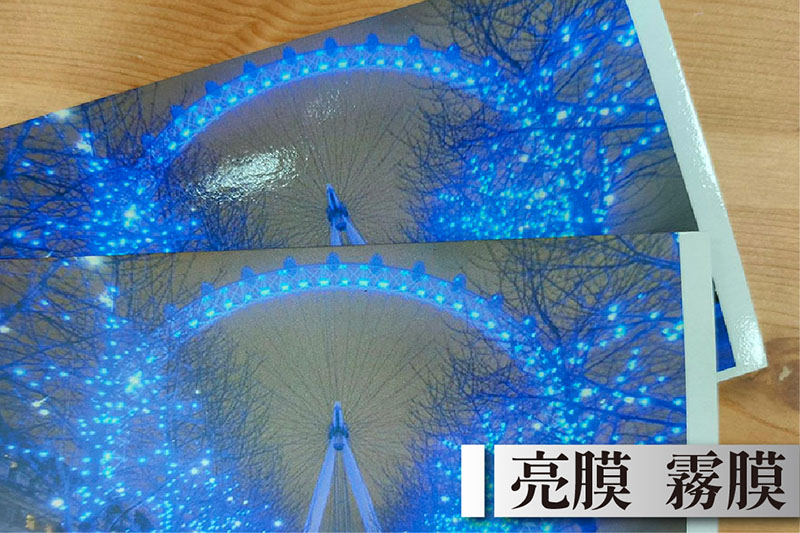

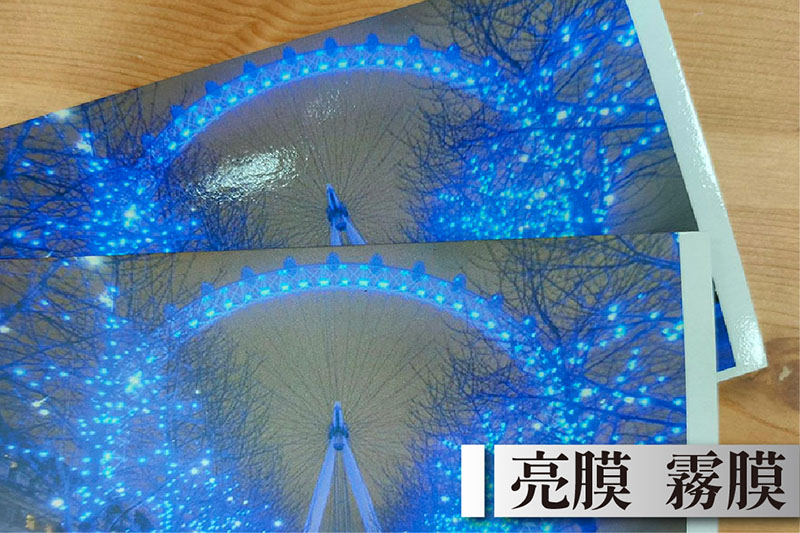

※Bright film

It is a layer of transparent colloidal film (somewhat similar to plastic wrap) on the surface of the printed matter. Because it has excellent moisture-proof, wear-resistant, anti-fouling characteristics, and has a glass-like luster effect, it is an advanced glazing method.

Applicable range: suitable for general printed matter, such as packaging color boxes, book covers, large posters, paper bags, etc.

※Fog film

It is a layer of matte colloidal film (a bit like a plastic wrap) on the surface of the printed matter, because it has excellent moisture-proof, wear-resistant, anti-fouling characteristics, and the surface is not reflective and soft to the touch. Light way, but the price is higher than the bright film.

Scope of application: Suitable for general printed matter, such as packaging color boxes, book covers, large posters, paper bags, etc.

|